Our team is ready to help you get your production project started

tin line,hairpin With cutting-edge technology.Discover OCTA Group's integrated solutions. HBA

EsploraExplore our range of products for HVACR,Data Centers,and tube processing

A comprehensive service ecosystem designed to ensure maximum performance for your work.

The best technological solutions tailored for your business

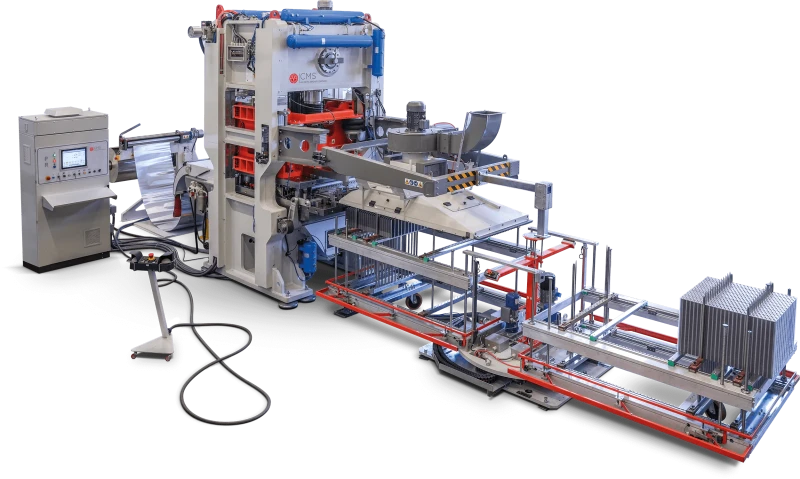

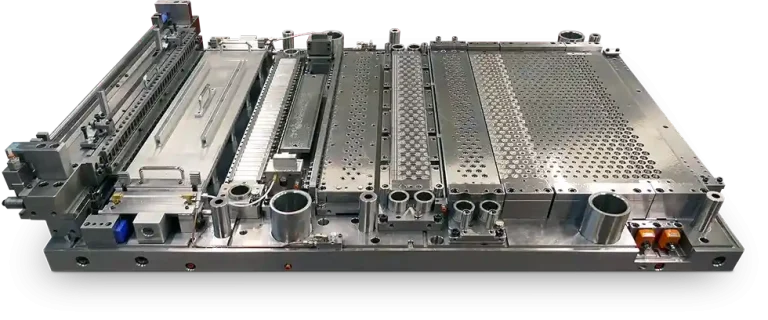

Fin Lines

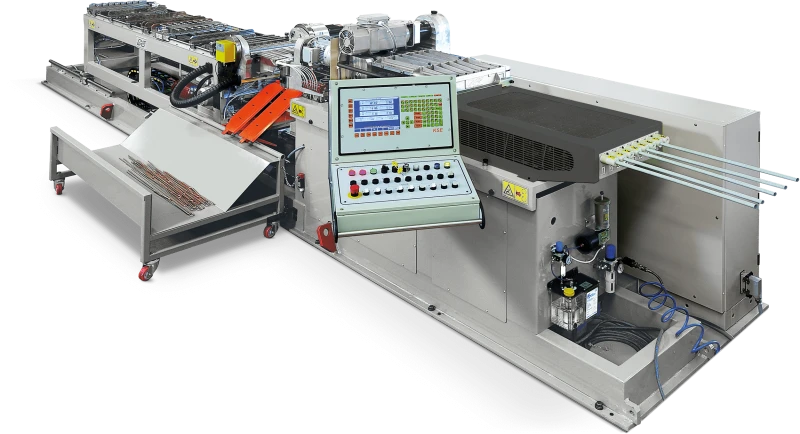

Tube bending machines

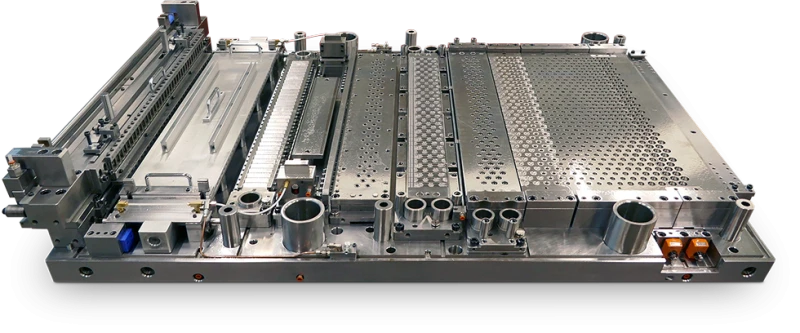

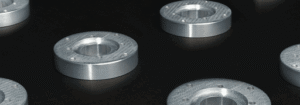

Fin Dies

Fin Lines

Fin Lines

Hairpin Benders

Multi-row Coilbender

Serpentine Benders

Complementary machines

Efficiency,flexibility,and productivity in a turnkey solution.

Service is the beating heart of every successful business: it’s not just about keeping products running but transforming them into tools that enhance productivity, optimize costs, and improve sustainability. With tailored solutions, global support, and a focus on efficiency, we ensure that every machine becomes a growth engine for our customers.

Service is not a cost—it’s an investment in the future of your business.

We manufacture progressive dies for fin packs,designed to ensure maximum production efficiency.

Additionally,we offer a comprehensive support and maintenance service,including the supply of new dies refurbishment of existing ones,and replacement of individual components when necessary.

This ensures that your production always maintains the highest levels of efficiency and reliability.

We offer tailored maintenance solutions to prevent failures and improve the performance of your machines. Thanks to the TCO Cube device,we continuously monitor the status of the equipment,enabling timely interventions and ongoing optimization of their lifecycle.

Choosing our service means relying on highly qualified technical support and advanced technologies to ensure maximum efficiency and productivity for your plants.

A team driven by passion, dedicated to designing and developing innovative, efficient, and sustainable technologies for tube processing, HVACR systems, and Data Centers—working in constant synergy with its clients. Our expertise is at your service to provide specific, cross-sector, and highly customized solutions, ensuring consultancy, training, and support at every stage of the production process.

Upload your project in the box to request your feasibility analysis.

We manufacture progressive dies for fin packs,designed to ensure maximum production efficiency.

Additionally,we offer a comprehensive support and maintenance service,including the supply of new dies refurbishment of existing ones,and replacement of individual components when necessary.

This ensures that your production always maintains the highest levels of efficiency and reliability.

We offer tailored maintenance solutions to prevent failures and improve the performance of your machines. Thanks to the TCO Cube device,we continuously monitor the status of the equipment,enabling timely interventions and ongoing optimization of their lifecycle.

Choosing our service means relying on highly qualified technical support and advanced technologies to ensure maximum efficiency and productivity for your plants.

The evolution of design starts with shapes:elegant tubular structures,flawless curves,and uncompromising creative freedom.With the new R42E,precision and aesthetics come together to create unique furniture solutions.

Explore new possibilities.

Made with high-quality materials,the molds are designed to ensure impeccable

precision in creating the required geometries.

Wherever you are,from the most populated areas to the most remote factories,

OCTA is ready to support you-remotely or on-site-through a team of highly

skilled professionals and technicians.

production plants

countries with OCTA machinery

installations

Gold-medal winning Paralympian athlete, “Monster” Mike Schultz launched BioDapt to create custom prosthetic equipment

Two new materials,Ceramic-filled and Tough Black,have been added to our material library

© Copyright 2025 – Terms of use Privacy Policy Cookie policy Whistleblowing

Designed by AdmarV